The energy you need might already be in your facility—you just haven’t captured it yet!

What once rotted in silence is now fueling the future. Across Taiwan, a revolution is fermenting: one that smells of waste but runs on innovation. From food scraps and livestock waste to wastewater from semiconductor plants, what was once unwanted is now powering farms and factories. It’s a shift from linear consumption to circular energy, and it’s happening on-site.

In place of large, centralized systems, Taiwan is pioneering small-scale, on-site circular energy solutions that repurpose organic waste into usable heat and power. Behind this quiet movement is a growing commercial relevance, and at its core, Biogas Combined Heat and Power (CHP) systems are fundamentally transforming how resources are managed.

⚙️ Biogas CHP: Simplified Efficiency

Biogas CHP systems use anaerobic digestion to extract methane-rich gas from organic waste. This gas powers a combustion engine that simultaneously produces electricity and heat, all in one integrated process. With energy efficiencies reaching up to 90%, CHP systems outperform conventional generators by recovering energy that would otherwise be lost as heat.

There are many ways to design this system, depending on the source of waste and the site’s energy needs. AMPOWER integrates German-engineered systems to the unique waste and energy challenges in Taiwan with proven uptime, stable output, and adaptability. Let’s look at two working models:

🏭 Distillery Waste & Food Sludge

In the food industry, waste is inevitable, but that doesn’t mean it should go to waste. At a food processing facility in Tainan City, organic sludge from production processes is now fueling its own energy supply.

🔁 Process Highlights:

- Sludge collection and dewatering

- Anaerobic digestion to generate biogas

- Biogas purification and pressurization

- CHP engine converts biogas to:

- Electricity (on-site use and grid export)

- Recoverable heat (used for steam or hot water)

- Digestate byproduct supports circular agriculture

📈 Benefits:

✔ Energy self-sufficiency

✔ Lower energy bills & carbon emissions

✔ Cost-effective waste management

💧 Wastewater-to-Energy Loop

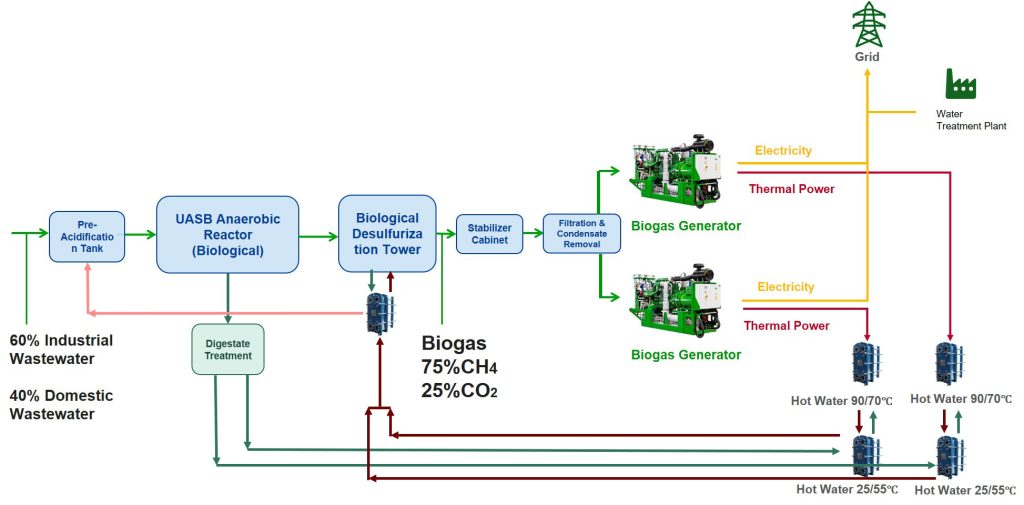

Wastewater treatment is typically energy-intensive, but a water treatment plant in Taoyuan City effectively converts liquid waste (60% industrial wastewater, 40% municipal wastewater) into clean energy.

🔁 Process Highlights:

- Pre-acidification tank prepares wastewater

- UASB anaerobic reactor generates biogas (75% CH₄, 25% CO₂)

- Biological desulfurization, drying, and gas storage

- CHP engines convert gas into:

- Electricity (on-site use and grid export)

- Heat distributed as hot water across the plant

📈 Benefits:

✔ Increases energy self-sufficiency of the treatment plant

✔ Slashes reliance on fossil fuels and external power

✔ Demonstrates a replicable, scalable municipal model

These projects show that biogas CHP systems can be flexibly designed:

✅ Whether the waste is solid sludge or liquid effluent

✅ Whether the location is farm, factory, or municipal facility

✅ Whether the heat required is high-temperature process heat or low-grade cleaning water

In all cases, the system transforms waste into a dual-purpose energy resource, saving costs and lowering emissions in one step.

🌏 Why This Matters to Businesses

Whether it’s an industrial site, a food processing plant, or public services, these systems are no longer niche. They’re strategic.

🌱 Measurable ESG impact: Carbon reduction, energy reuse, waste diversion

💡 Energy efficiency: Dual energy output from single fuel source

🔒 Operational resilience: Power security during grid fluctuations or blackouts

💰 Economic return: Lower energy bills, monetized waste, higher ROI

🌍 Enabling circular economy: Turn environmental liabilities into assets

The future of energy isn’t a distant breakthrough, it’s already happening beneath our feet, in what we used to throw away. In Taiwan, waste is now a resource. And with the right technology and vision, every site has the potential to become its own clean power plant.

Let AMPOWER’s CHP systems help you establish a new chapter in circular energy!