A brief flicker may seem like nothing, barely noticeable. But in the milliseconds it takes for the lights to blink, a delicate architecture of information systems can collapse. And with it, production halts, equipment fails, safety risks rise, and trust is lost.

In today’s high-stakes industries, even brief power interruptions can be catastrophic. Knowing this, more operations are turning to Dynamic UPS (DUPS) for uninterruptible power. They don’t just step in during outages; they work continuously, conditioning and stabilizing power supply even before issues arise.

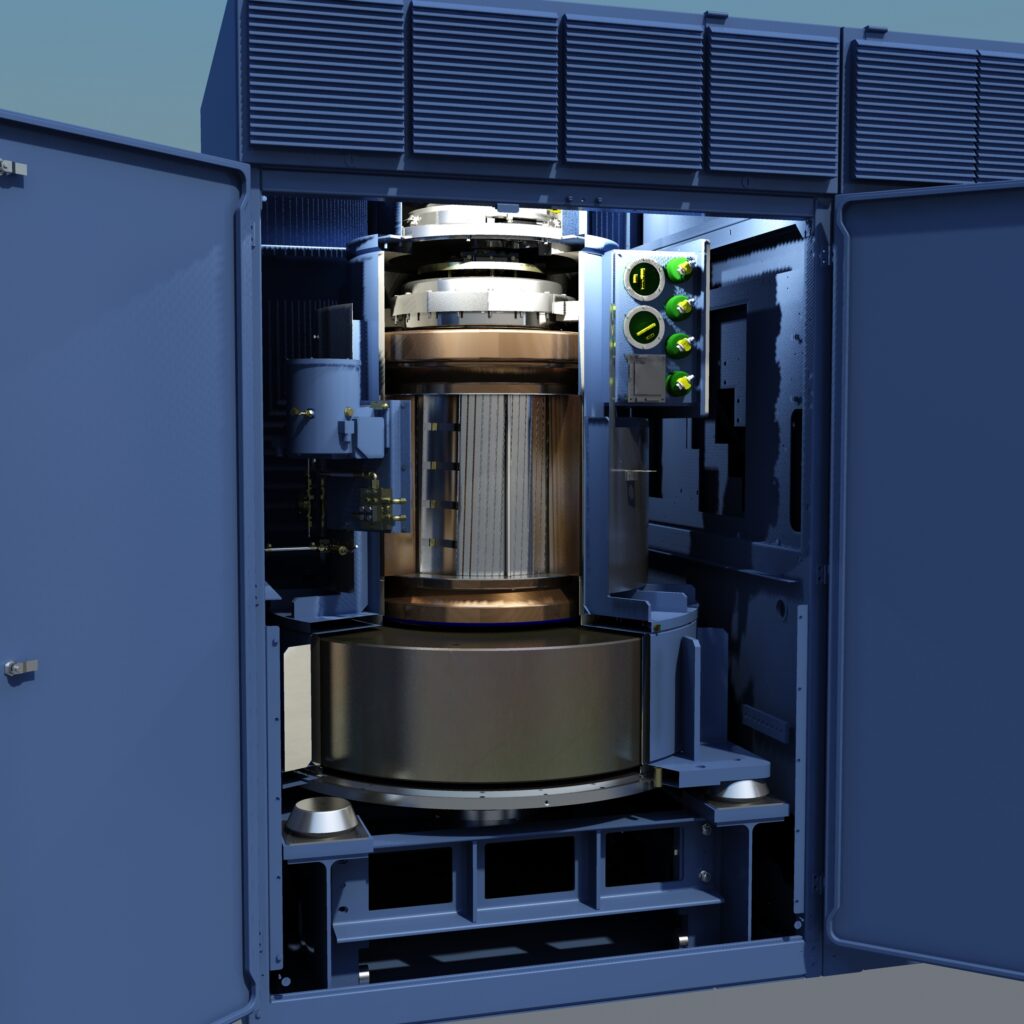

A Closer Look: How Dynamic UPS Works

DUPS operates on a straightforward mechanical principle: using motion from the motor-generator and flywheel to store energy and maintain power quality. During normal operation, utility power spins the system and filters out surges, sags, and frequency issues, ensuring the power delivered to sensitive equipment is clean and consistent.

If a power failure occurs, the high-speed flywheel immediately takes over, releasing stored kinetic energy to maintain the power supply without interruption. This bridge lasts 10-60 seconds—often the critical margin between stability and disruption. If extended backup is needed, a diesel generator starts within seconds to carry the load. Once stable power returns, the transition is seamless.

This mechanical approach to energy storage and delivery offers a radically different proposition: less electronic complexity, more resilience.

Rotary Architecture, Proven Performance

DUPS offers several key advantages over conventional battery-based (static) alternatives, especially when performance, longevity, and resilience are non-negotiable:

⚡ Built to Last: Fewer electronic parts, no reliance on batteries. These systems often operate for 20+ years with minimal degradation.

🌱 Efficient by Design: Operating at over 96% efficiency, they minimize energy waste and reduce operating costs at scale.

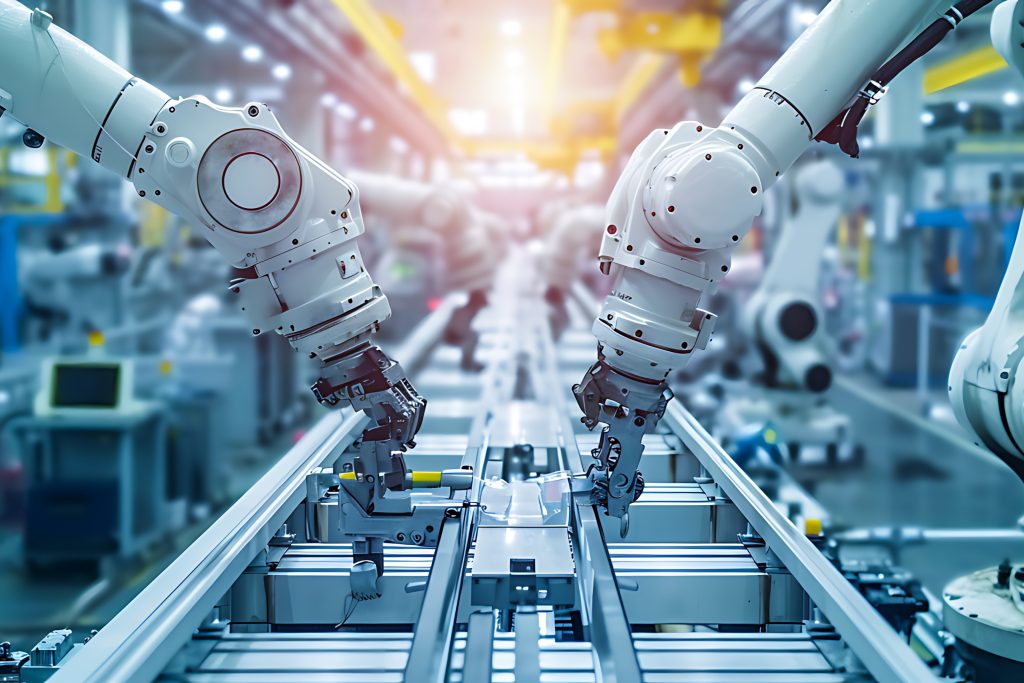

🏭 Industrial-Grade Resilience: Designed to perform reliably in environments with heat, dust, and vibration, ideal for industrial and manufacturing settings.

🛡️ High Fault Tolerance: Can isolate electrical faults without impacting critical systems, adding an extra layer of operational stability.

🔧 Flexible Scaling: Modular configurations support N+1 or 2N redundancy, adapting easily to growing or tiered infrastructure.

Designed for the Real World

More than uptime, it’s about ease of ownership. DUPS are also practical, efficient, and easier to live with day-to-day:

🧯 No Batteries, No Hazards: No chemical waste, fire risks, or end-of-life disposal concerns.

🌬️ Lower Cooling Demand: Minimal heat output eases HVAC load and reduces infrastructure stress.

🌏 Sustainably Smart: High efficiency + no battery = lower carbon footprint.

🧰 Predictable Maintenance: Mechanical wear is gradual and measurable, making servicing simple and scheduled.

💰 Lower Total Cost Over Time: Fewer parts, longer life, and less downtime mean reduced ownership cost year after year.

Planning for Your Business Resilience

AMPOWER has worked closely with clients in high-stakes environments in Taiwan: semiconductor fabs, data centers, and critical manufacturing to implement DUPS that support around-the-clock operation with minimal intervention.

If you’re building new infrastructure or reinforcing existing systems, DUPS gives you industrial-grade protection, predictable performance, and lasting value. Get in touch to explore what fits your operation best!